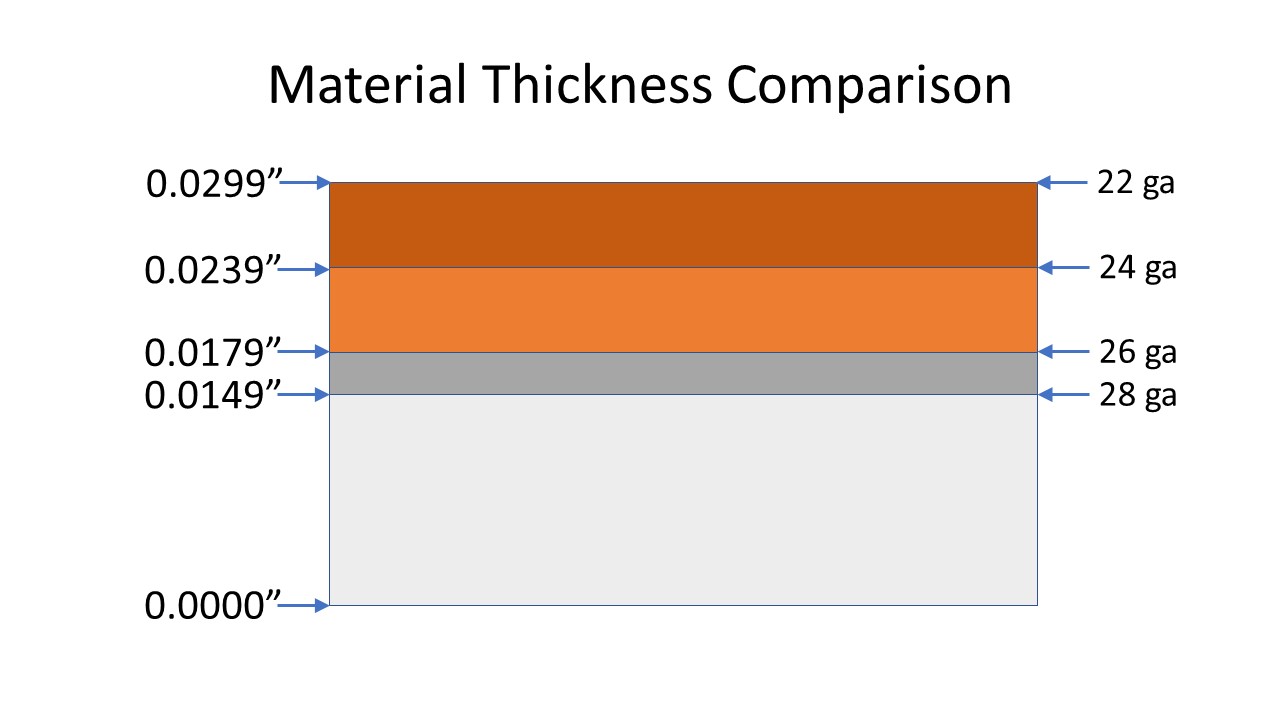

Material Thickness

24 gauge steel is the industry standard material for most commercial and high end residential metal roofing and flashing applications. 22 gauge is sometimes used for applications where oil canning might be expected with 24 gauge. 26 and 28 gauge are typically used for residential, light commercial, and agricultural applications.

- 24 gauge is 60% thicker than 28 gauge

- 24 gauge is 34% thicker than 26 gauge

Material Finish (Paint)

Several factory-applied paint finish types are available. The reliability of these finishes depends on several factors. The two most critical factors are resin type and pigment material.

The three most common paint finish types are Kynar, SMP and Polyester.

Finish warranty periods can be similar between systems with respect to adhesion, but Kynar systems outperform SMP and Polyester systems when it comes to fading and chalking.

- Kynar 500 resin is composed of at least 70% PVDF, a compound similar to Teflon. Ceramic solids are used for pigment. It is considered the most resistant to chalking and fading.

– PVDF is more resistant to chemical and UV degradation compared to the other paint systems, and is the benchmark system for chalking resistance.

– Ceramic pigments are inherently resistant to color degradation, resulting in relatively small changes in color over time.

- SMP (Silicone Modified Polyester) finishes use a Silicone/Polyester resin and an organic (plastic) filler for pigment. It is considered to be a superior finish over Polyester, but lower performing than Kynar finishes.

– In SMP systems, Silicone improves the gloss retention and weather retention of polyester coatings. SMP systems retain their gloss longer when compared to Polyester systems, but do not perform as well as Kynar systems.

- Polyester finishes are similar to SMP finishes, except that the resin does not contain Silicone. Polyester systems are the least expensive, and are the least resistant to fading and chalking.